SIGNKING SKM-898-04 Multi Vision Mounter

SIGNKING SKM-898-04 Multi Vision Mounter

MOQ : piece

Lead Time : Days

Seller Support : Trade Authenticity Guaranteed & Accepting

Payment : L/C,T/T,Western Union, Money Gram, Credit Card, Paypal

Product details

Supply Ability

- Warranty(Year):1 Year

Packaging & Delivery

- Packaging: piece

Product Specifications

Product Description

This machine launched to market in 2007, it gets positive feedback from the Southeast Asia countries: constancy, high cost performance, multi functions, etc. We have up to 65% re-order from the India customers.

Equipment Features

● optical image capture the position, the flight of the technology;

● X, Y, Z axis-wide application of magnetic levitation linear motor, no friction, no resistance, high-speed, long service life;

● Built-in AOI detection function (optional);

● can mount 0201-45mmIC components;

● Best can be realized 7000CPH patch speed;

● up to 80 feeders can be placed;

● equipped with a variety of nozzle and can be automatically replaced;

● mount speed SKM-898-04: 7000CPH

● Equipment Size: 1415mm (L) X1145mm (W) X1335mm (H)

Structure Summary - machine vision systems, electrical power systems installed system software control system for motion control system LCD display unit

This machine adopts high-grade stainless steel and powder technology imported from Japan produced beautiful and durable. Anti-bleaching powder anti-corrosion process

Technical Features

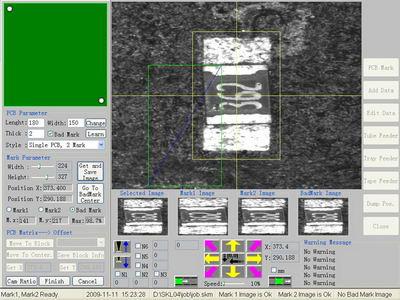

Parts Identification Camera

The use of fast non-stop shooting method, taking pictures of parts identification process to achieve high-speed flight in the right position.

SKM-898-04Nozzle

All nozzle axis movements are using the linear motor direct drive, and with position feedback and vacuum check feature. High-precision equipment quote。

X, Y-axis

X, Y-axis using the linear motor linear drive, linear encoder to do the whole closed-loop control, the performance of higher-speed and placement to achieve superior accuracy。

PCB width

PCB board width can be adjusted only in the control software interface PCB data set, the machine can adjust the width guide.

Built-in AOI

Built-in AOI function (optional) can be checked before loading the paste solder paste printing accuracy and gaps, and in the post-paste inspection equipment installed paste parts precision and mistakes can replace SMT placement machine before and after the AOI equipment . (Except after furnace)

Most feed tray can hold 10

A rich variety of feeder options

Can be high-mounted 8mm, 12mm, 16mm, 24mm, 32mm, 44mm, 56mm feeders.

Three-rail transportation

Specifications